3D printing technologies

Areas of application

Use in practice in...

Prototyping

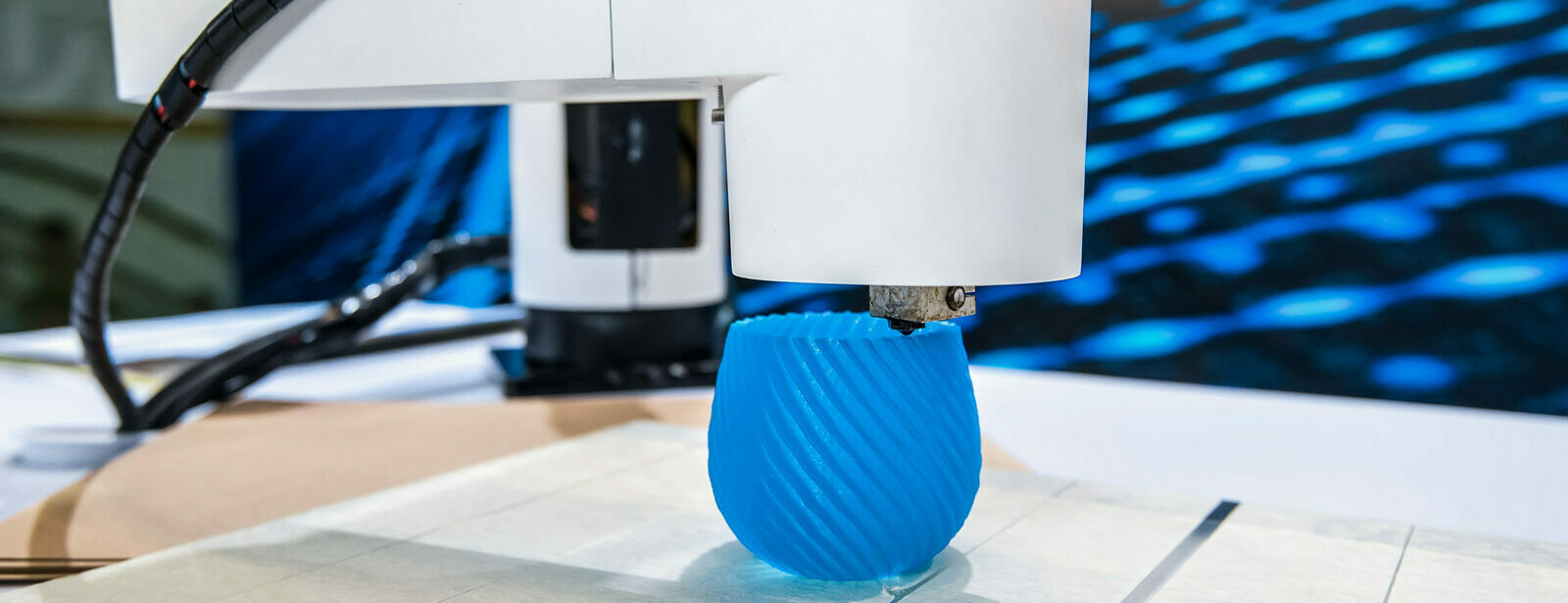

3D printing has sparked a revolution in prototyping in recent years. With this innovative technology it is possible to produce high-precision and customized prototypes within a very short time. Whether it's simple dummy components, complex functional prototypes or even initial samples close to series production - 3D printing offers a multitude of possibilities.

One of the biggest advantages of 3D printing compared to traditional prototyping is the rapid availability of parts. While conventional processes often take weeks to complete a prototype, 3D printing can be completed within a few hours or days. This allows developers to quickly test and revise their ideas, which significantly speeds up the entire development process. In addition, 3D printing offers a high degree of flexibility when designing the prototypes. With additive manufacturing technology, complex geometries and fine details can be easily implemented. This opens up completely new possibilities for product development and allows designers to fully exploit their creative ideas.

Another major advantage of 3D printing for prototyping is the cost savings. Compared to traditional processes, which often require expensive tools and molds, 3D printing is significantly cheaper. This allows companies to create multiple iterations of a prototype and test different design options without having to spend a fortune.

Overall, 3D printing has revolutionized prototyping and offers an efficient and cost-effective solution for companies and developers. The rapid availability of parts, flexibility in design and cost savings make 3D printing an indispensable technology in the development process.

3D printing offers a variety of opportunities to bring products to market faster and more effectively.

Modelling

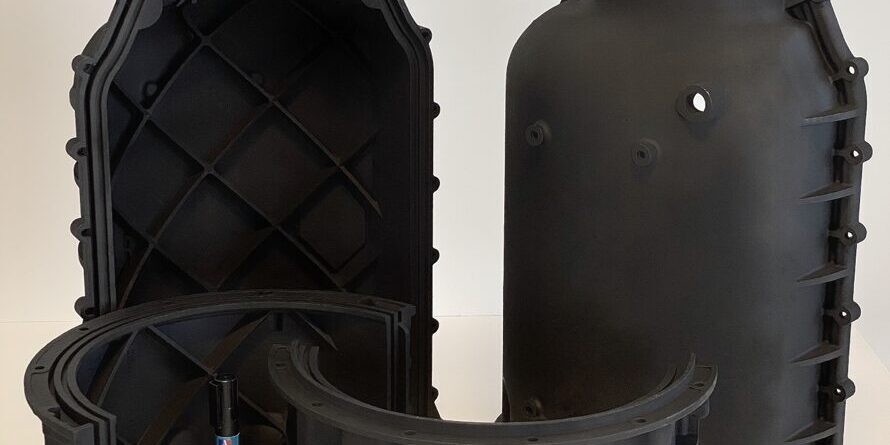

Small and medium-sized batches

Since additive processes mostly do not rely on expensive and specially adapted tools and means of production, they do not require considerable investment in advance. As such, AM processes are suitable for cost-effective small-batch production.

The biggest challenge is how to achieve component and material properties with AM processes that are at the same level as those provided by traditional manufacturing methods.

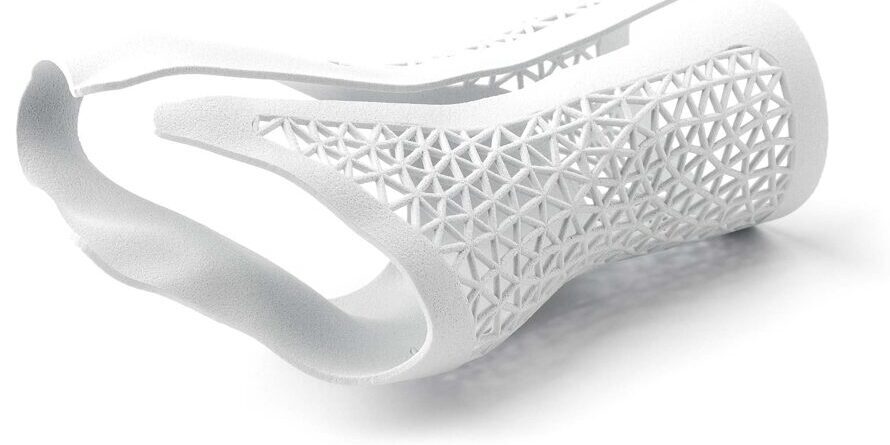

Customization

Individualisation and customisation in 3D printing enables the production of components that are specifically tailored to the individual case. It is even possible to produce these fully customised components economically. Particularly in medical technology and prosthetics, customised one-off productions are well-known and successfully used. For example, 3D printing can be used to produce customised implants, prostheses or orthopaedic aids that are precisely tailored to the needs and requirements of the patient. This enables an optimal fit and functionality, which can lead to an improved quality of life and recovery. In addition, customisation in 3D printing also opens up new possibilities in other industries such as the automotive industry, design or architecture. The flexibility and precision of 3D printing makes it possible to realise complex shapes and structures that would be difficult or impossible to implement using conventional manufacturing methods. This makes it possible to create products and components that are not only functional but also aesthetically pleasing and meet the individual preferences and needs of customers. Individualisation in 3D printing thus opens up new perspectives and potentials for the manufacturing industry.

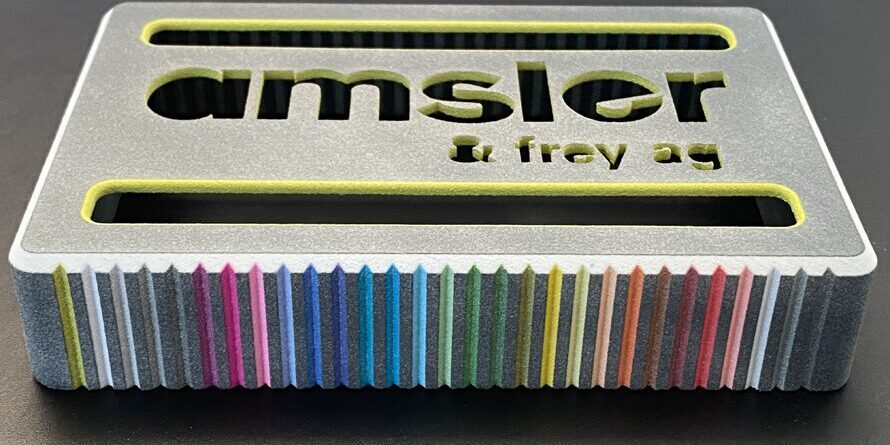

Creative area / freedom of construction

The additively manufactured components can be produced with almost any geometry without additional costs. Functions are optimally achieved with minimal material input and structures are reduced to the bare minimum.

In order to create structures with added value through the process-specific design freedoms and functional integration, the designers have to rethink their approach, in contrast to classic processes.